What is the Price of Injection Molding? Detailed Price Guide

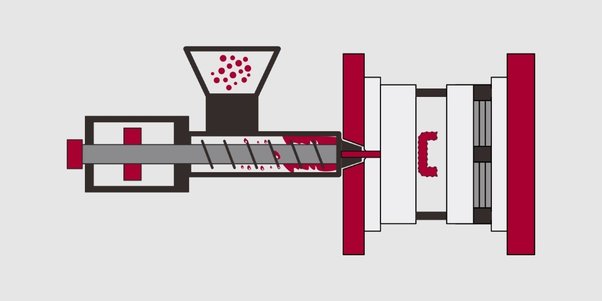

Injection molding is a versatile manufacturing process used to produce a wide range of plastic parts. Understanding the price of injection molding is essential for businesses planning to utilize this technology. This detailed price guide will explain the factors affecting the cost, typical price ranges, and ways to optimize expenses while maintaining quality.

Factors Influencing the Price of Injection Molding

Complexity of the Design

The complexity of the mold design significantly impacts the price of injection molding. Simple molds with basic shapes and fewer details cost less. Complex molds with intricate designs, multiple parts, or tight tolerances increase the cost due to additional time and expertise required in manufacturing.

Material of the Mold

The type of material used for the mold also affects the price of injection molding. Common materials include tool steel, stainless steel, and aluminum.

- Tool Steel: Offers a good balance of strength, hardness, and wear resistance, but is more expensive.

- Stainless Steel: Provides excellent corrosion resistance, ideal for medical and food-grade applications.

- Aluminum: Cheaper and easier to machine, suitable for low-volume production or prototypes.

Size of the Mold

The size of the mold plays a crucial role in determining the price of injection molding. Larger molds require more material and extensive machining, thus increasing the cost. Smaller molds, requiring less material and time, are generally cheaper.

Number of Cavities

The number of cavities in a mold impacts the price of injection molding. Single cavity molds are less expensive but produce one part per cycle. Multi-cavity molds are more costly but can produce multiple parts per cycle, reducing the cost per part in high-volume production.

Precision and Tolerance Requirements

High precision and tight tolerance requirements increase the price of injection molding. Standard tolerances are cheaper due to less demanding machining processes. High precision molds require advanced techniques and additional quality checks, raising the overall cost.

Additional Features

Incorporating additional features into the mold design affects the price of injection molding.

- Hot Runners: Increase costs but reduce waste and cycle times.

- Insert Molding: Adds to the complexity and cost of the mold.

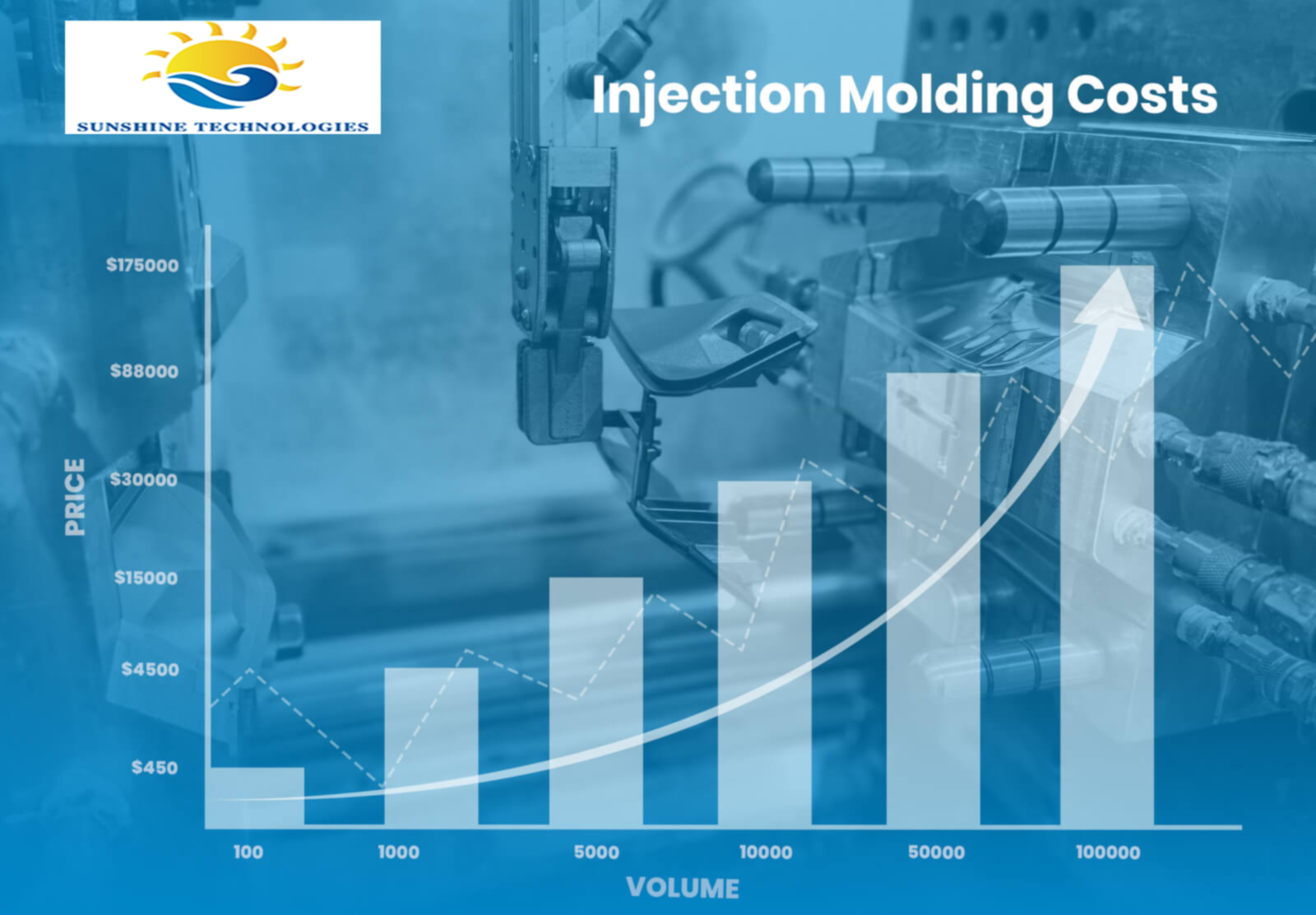

Typical Price Ranges

Small, Simple Molds

- Aluminum Molds: $3,000 – $10,000

- Tool Steel Molds: $5,000 – $15,000

Medium Complexity Molds

- Aluminum Molds: $10,000 – $25,000

- Tool Steel Molds: $15,000 – $50,000

Large, Complex Molds

- Tool Steel Molds: $50,000 – $100,000+

- Stainless Steel Molds: $60,000 – $120,000+

Cost Optimization Strategies

Prototyping with Aluminum

Starting with aluminum molds for prototypes or low-volume runs can reduce initial costs. Aluminum is easier to machine and less expensive, making it ideal for testing designs before committing to more costly tool steel molds.

Simplifying the Design

Simplifying the mold design can help lower the price of injection molding. Reducing the complexity of parts and minimizing the number of intricate details decreases machining time and material usage, resulting in cost savings.

Utilizing Multi-Cavity Molds

For high-volume production, investing in multi-cavity molds can reduce the cost per part over time. Although the initial investment is higher, producing multiple parts per cycle increases efficiency and lowers long-term expenses.

Selecting the Right Manufacturer

Choosing a manufacturer with a good reputation and experience in injection molding can optimize costs. Reliable manufacturers may offer competitive pricing and better quality, reducing the need for rework and ensuring consistent production.

Common Applications of Injection Molding

Automotive Industry

The automotive industry heavily relies on injection molding for producing various components such as dashboards, bumpers, and interior parts. The precision and durability offered by this process make it a preferred choice.

Consumer Electronics

Consumer electronics companies use injection molding to manufacture components like casings, connectors, and buttons. The ability to produce intricate designs with high precision is crucial in this industry.

Medical Devices

In the medical field, precision and quality are paramount. Injection molding is used to produce medical devices and components such as syringes, enclosures, and diagnostic equipment, adhering to stringent quality standards.

Packaging

The packaging industry benefits from injection molding for producing containers, caps, and other packaging materials. The cost-effectiveness and rapid production capabilities are significant advantages.

FAQs About the Price of Injection Molding

What is the lead time for injection molding services?

The lead time varies depending on the complexity and volume of the order. Generally, it ranges from a few weeks to a couple of months.

How do I ensure the quality of products from an injection molding service?

Choose a manufacturer with certifications such as ISO 9001. Conduct regular quality checks and request samples throughout the production process.

What types of materials can be used in injection molding?

A wide range of materials can be used, including thermoplastics, elastomers, and specialized materials. Discuss your specific needs with the manufacturer.

Is it cost-effective to use injection molding for small production runs?

Yes, it offers cost-effective solutions for both small and large production runs. The scalability allows for flexibility in order sizes.

Can manufacturers handle complex and intricate designs?

Yes, they are equipped with advanced technology to handle complex and intricate designs with high precision.

Conclusion

Understanding the price of injection molding involves considering various factors like mold complexity, material, size, and additional features. By knowing these factors and applying cost optimization strategies, businesses can make informed decisions to achieve high-quality production at competitive prices. Whether you’re in the automotive, electronics, medical, or packaging industry, injection molding offers versatile solutions to meet your manufacturing needs efficiently.

Conclusion

Injection molding service in China offers numerous benefits, making it a preferred choice for many industries. From cost efficiency to high precision, it provides businesses with a reliable and effective manufacturing solution. Understanding the process, benefits, and future trends helps in making informed decisions. Whether you need to produce automotive parts, medical devices, or consumer electronics, injection molding service in China is a dependable option.

Import from China Guide

For beginners who don’t know what to buy & sell, have 0 experience about importing from China, you can get all questions answered in this tutorial.

(10 video courses included)