Top Injection Molding Service in China: The Ultimate Guide

Injection molding service in China is a cornerstone of modern manufacturing. This comprehensive guide delves into its benefits, processes, and why China is a leader in this field. Businesses seeking cost-effective and high-quality production solutions will find this guide invaluable.

Why Choose Injection Molding Service in China?

1. Cost-Effective Manufacturing

Injection molding service in China is known for its cost-effective solutions. The availability of affordable raw materials and labor significantly reduces production costs. Businesses can produce large quantities of parts at a lower expense compared to other countries.

2. High-Quality Production

Chinese manufacturers are renowned for their high-quality production standards. They use advanced machinery and skilled labor to ensure precision and consistency. Products manufactured through injection molding service meet international quality standards.

3. Quick Turnaround Times

One of the major advantages of injection molding service is the fast turnaround times. Efficient production processes and streamlined logistics ensure quick delivery. This is especially beneficial for businesses with tight deadlines.

4. Diverse Material Options

Injection molding service offers a wide range of material options. Manufacturers can use various types of plastics and resins. This allows for flexibility in designing and producing parts with specific properties.

5. Extensive Expertise

Chinese manufacturers have extensive expertise in injection molding. Many companies have decades of experience. This ensures reliable and precise production, meeting diverse client requirements.

The Injection Molding Process in China

1. Design and Prototyping

The first step in the injection molding service is design and prototyping. Engineers create detailed CAD designs. These designs are converted into prototypes for testing and validation.

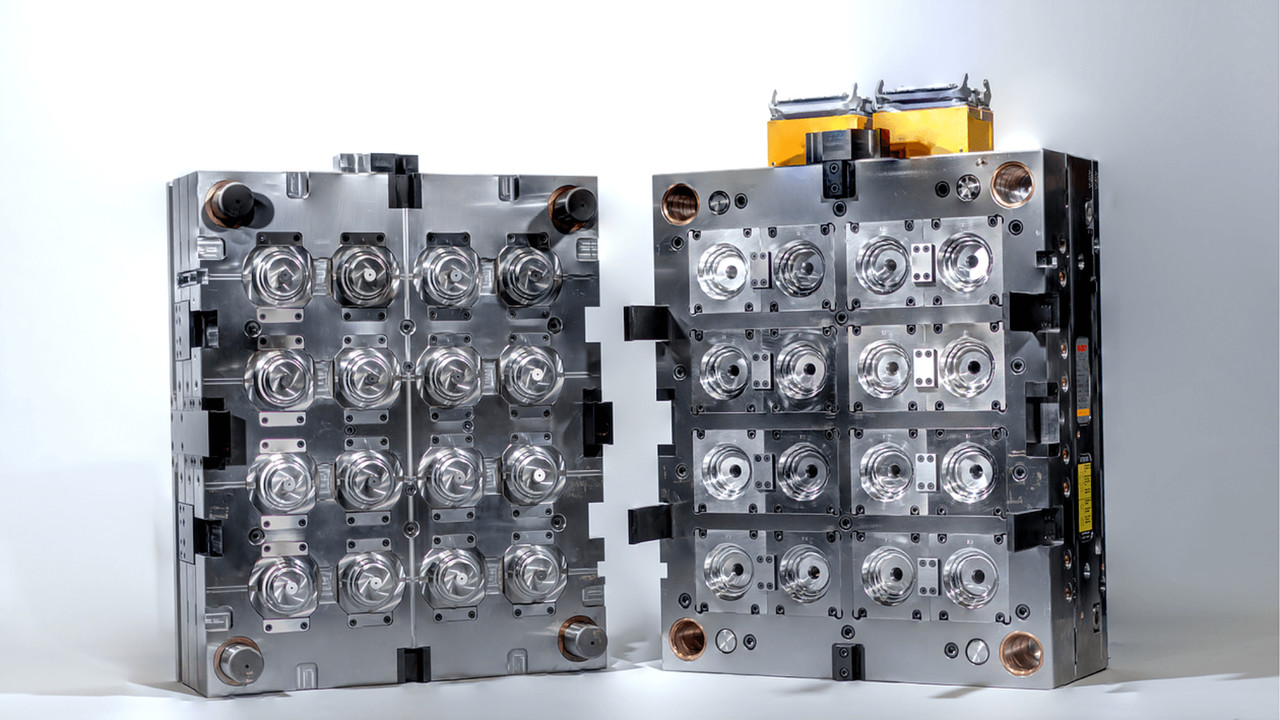

2. Mold Creation

Once the prototype is approved, the mold creation process begins. Molds are typically made from steel or aluminum. Precision in mold making is crucial to ensure the accuracy of the final product.

3. Material Selection

Choosing the right material is essential in injection molding service in China. Different materials offer various properties. Manufacturers provide a selection of plastics and resins suited for different applications.

4. Injection Molding

During the injection molding process, the chosen material is heated until molten. It is then injected into the mold under high pressure. After cooling, the material solidifies into the desired shape.

5. Quality Assurance

Quality assurance is a critical component of injection molding service in China. Manufacturers perform various tests and inspections to ensure products meet the required standards. This includes dimensional checks and performance testing.

Advantages of Injection Molding Service in China

1. Cost Efficiency

One of the main advantages of injection molding service in China is cost efficiency. Lower labor and material costs lead to reduced production expenses. This makes it an attractive option for businesses looking to optimize their budgets.

2. High Precision and Consistency

Injection molding service is known for its high precision and consistency. Advanced machinery and skilled technicians ensure that parts are produced with minimal variations. This is crucial for applications requiring tight tolerances.

3. Scalability

Injection molding service offers excellent scalability. Manufacturers can handle both small and large production runs. This flexibility is ideal for businesses that need to scale their operations.

4. Customization Options

Chinese manufacturers provide extensive customization options. Clients can choose from a variety of materials, colors, and finishes. This is important for creating parts that meet specific design and functional requirements.

5. Environmental Sustainability

Many injection molding service providers in China are focusing on sustainability. They use eco-friendly materials and processes. This helps in reducing the environmental impact of manufacturing.

Industries Utilizing Injection Molding Service in China

1. Automotive Industry

The automotive industry extensively uses injection molding service in China. Parts like dashboards, bumpers, and interior components are commonly produced using this method. The precision and durability of injection-molded parts are critical for automotive applications.

2. Consumer Electronics

Injection molding service in China plays a significant role in the consumer electronics industry. Products like smartphone cases, connectors, and various internal components are manufactured using this technique. The ability to produce intricate designs with high accuracy is a key advantage.

3. Medical Devices

The medical industry benefits greatly from injection molding service in China. Devices such as syringes, diagnostic tools, and surgical instruments are produced using injection molding. The high-quality standards and material options are essential for medical applications.

4. Packaging Industry

Injection molding service is widely used in the packaging industry. Items like bottles, caps, and containers are efficiently produced using this method. The ability to create customized packaging solutions is a significant benefit.

5. Toy Manufacturing

The toy industry also relies on injection molding services. Products such as action figures, game pieces, and various toy components are made using this technique. The versatility of materials and colors available is advantageous for toy manufacturers.

Selecting the Right Injection Molding Service in China

1. Conduct Thorough Research

When selecting an injection molding service in China, thorough research is essential. Look for manufacturers with positive reviews and a strong reputation. Check their portfolio to see examples of their work.

2. Assess Capabilities

Evaluate the capabilities of potential manufacturers. Ensure they have the necessary equipment and expertise to handle your project. This includes assessing their ability to work with your chosen materials and meet your quality standards.

3. Verify Quality Control Processes

Quality control is crucial in injection molding services in China. Verify that the manufacturer follows strict quality assurance protocols. This includes regular inspections and adherence to international standards.

4. Compare Costs

While cost is a significant factor, it should not be the sole criterion. Compare quotes from different manufacturers. Ensure that you are getting the best value for your investment without compromising on quality.

5. Ensure Good Communication

Good communication is vital when working with an injection molding services in China. Choose a manufacturer who communicates clearly and promptly. This helps in resolving any issues quickly and ensures smooth project execution.

Contact with us for right injection molding service in China

Future Trends in Injection Molding Service in China

1. Advanced Materials

The use of advanced materials is a growing trend in injection molding service. Innovations in polymers and composites are enhancing the performance of molded parts. These materials offer improved strength, durability, and sustainability.

2. Automation and Robotics

Automation is increasingly being integrated into injection molding services in China. Robotics and automated systems improve efficiency and reduce labor costs. This leads to faster production times and consistent quality.

3. Digital Manufacturing

Digital manufacturing technologies are transforming injection molding services in China. The use of IoT and AI for monitoring and controlling the process is becoming more common. This enhances precision and allows for real-time adjustments.

4. Focus on Sustainability

Sustainability is becoming a major focus in injection molding services in China. Manufacturers are adopting eco-friendly materials and processes. This reduces the environmental impact of production and meets growing consumer demand for sustainable products.

5. Customization and Personalization

The demand for customization and personalization is on the rise. Injection molding services is evolving to offer more options for tailored products. This trend is driven by consumer preferences and advances in technology.

Tips for Successful Injection Molding Projects

1. Provide Clear Specifications

Provide clear and detailed specifications to the manufacturer. This ensures they understand your requirements and can deliver accurate results. Detailed specifications help in avoiding misunderstandings and errors.

2. Use Prototyping

Prototyping is a crucial step before full-scale production. It allows for testing and refining the design. This helps in identifying and correcting any issues early on, ensuring the final product meets your expectations.

3. Choose the Right Materials

Selecting the right materials is essential for a successful injection molding project. Different materials have unique properties. Discuss options with the manufacturer to choose the best material for your application.

4. Implement Quality Control

Implement strict quality control measures throughout the production process. Regular inspections and tests ensure that products meet specifications. This reduces the risk of defects and enhances overall quality.

5. Maintain Good Communication

Maintain clear and constant communication with the manufacturer. This helps in addressing any issues or changes promptly. Good communication is key to a successful project.

Frequently Asked Questions (FAQs)

1. What is injection molding service?

Injection molding service in China involves producing parts by injecting molten material into a mold. It is a widely used manufacturing process for creating plastic parts.

2. Why is injection molding service in China cost-effective?

Injection molding service in China is cost-effective due to lower labor and material costs. Efficient production processes further reduce expenses.

3. What materials are used in injection molding services in China?

A variety of materials, including thermoplastics, resins, and elastomers, are used. The choice of material depends on the specific application and requirements.

4. How long does the injection molding process take?

The duration of the injection molding process varies. It depends on the complexity and size of the project. However, injection molding service in China is known for its fast turnaround times.

5. Can injection molding services in China handle large production runs?

Yes, injection molding services in China can handle large production runs efficiently. This scalability makes it suitable for high-volume manufacturing.

6. What industries benefit from injection molding services in China?

Industries such as automotive, electronics, medical, packaging, and toys benefit from injection molding services in China. It is a versatile manufacturing method.

7. How can I ensure the quality of products from injection molding services in China?

Ensure that the manufacturer follows strict quality control measures. Check for certifications and positive reviews from previous clients.

8. Are there customization options available in injection molding services in China?

Yes, manufacturers offer extensive customization options. This includes different materials, colors, and finishes to meet specific requirements.

9. What are the environmental impacts of injection molding services in China?

Many manufacturers are adopting eco-friendly materials and processes. This helps in reducing the environmental impact of injection molding.

10. How do I choose the right injection molding service in China?

Research and evaluate manufacturers, consider cost and quality, ensure good communication, and verify quality assurance measures.

Conclusion

Injection molding service in China offers numerous benefits, making it a preferred choice for many industries. From cost efficiency to high precision, it provides businesses with a reliable and effective manufacturing solution. Understanding the process, benefits, and future trends helps in making informed decisions. Whether you need to produce automotive parts, medical devices, or consumer electronics, injection molding service in China is a dependable option.

Import from China Guide

For beginners who don’t know what to buy & sell, have 0 experience about importing from China, you can get all questions answered in this tutorial.

(10 video courses included)