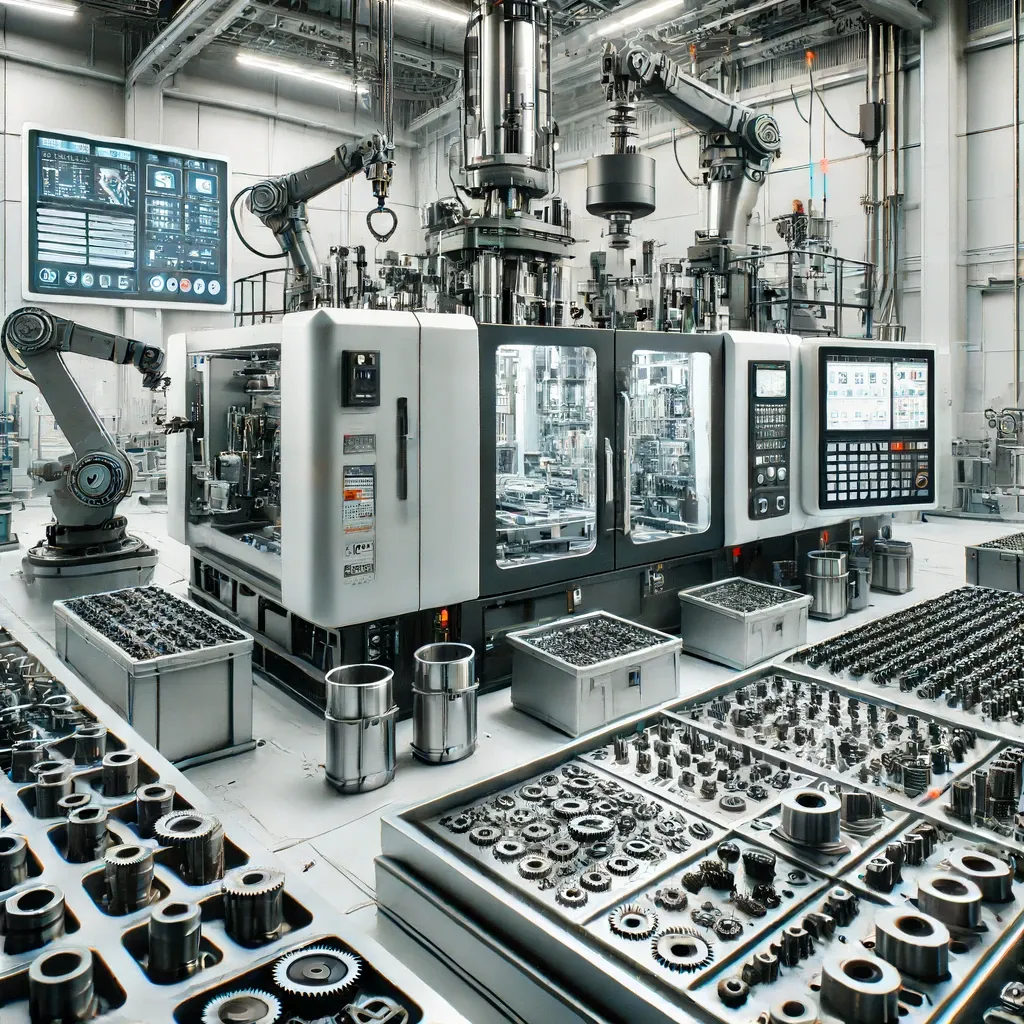

Top Applications of Injection Molding in Various Industries

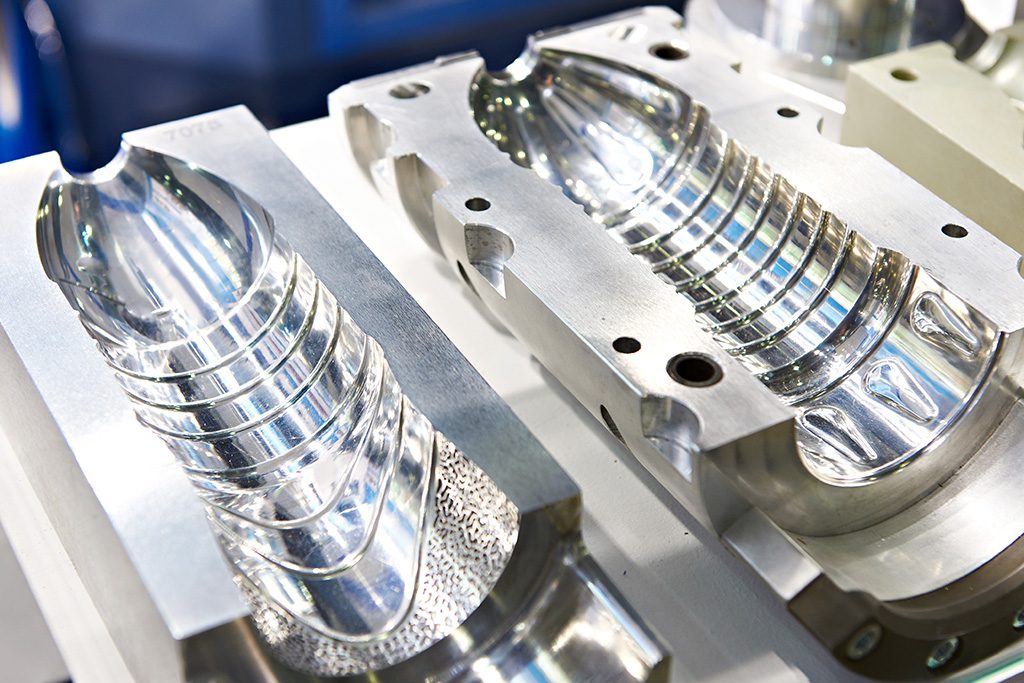

Injection molding is a versatile manufacturing process that creates plastic parts and components. This method involves injecting molten plastic into a mold, which then cools and solidifies to form the desired shape. Injection molding is widely used in numerous industries due to its efficiency, precision, and cost-effectiveness. In this blog post, we will explore the top applications of injection molding in various industries.

Automotive Industry

Manufacturing Auto Parts

One of the primary applications of injection molding in the automotive industry is the manufacturing of auto parts. Many components, including dashboards, bumpers, and interior panels, are produced using this method. Injection molding allows for the creation of complex shapes and intricate designs, ensuring high-quality and durable parts.

Lightweight Components

Injection molding also helps in producing lightweight components for vehicles. By using materials such as plastic and composites, manufacturers can reduce the overall weight of the vehicle, leading to improved fuel efficiency and performance. This application is crucial in the automotive industry’s push towards more sustainable and energy-efficient solutions.

Medical Industry

Medical Devices

Injection molding plays a vital role in the production of medical devices. Items like syringes, catheters, and IV components are often manufactured using this process. The precision and accuracy of injection molding ensure that these devices meet stringent medical standards and provide reliable performance.

Lab Equipment

Lab equipment, such as petri dishes, test tubes, and pipettes, are also produced through injection molding. The ability to create consistent and high-quality products is essential in the medical field, where accuracy and reliability are critical.

Consumer Goods

Household Items

Injection molding is extensively used in the production of household items. Products like storage containers, kitchen utensils, and toys are often manufactured using this method. The versatility of injection molding allows for the creation of various shapes and sizes, catering to diverse consumer needs.

Electronic Casings

Many electronic devices, such as remote controls, game consoles, and smartphones, have casings made through injection molding. This process ensures that the casings are durable, lightweight, and have a smooth finish, providing both protection and aesthetic appeal.

Packaging Industry

Food Packaging

Injection molding is commonly used in the packaging industry to produce food containers, bottles, and caps. The ability to create airtight and leak-proof containers is essential for preserving the freshness and quality of food products.

Cosmetic Packaging

Cosmetic packaging, including jars, tubes, and compacts, is also manufactured using injection molding. The precision of this method ensures that the packaging is both functional and visually appealing, enhancing the overall consumer experience.

Electronics Industry

Component Housings

Injection molding is crucial in producing housings for electronic components. Items like connectors, switches, and sensors are often encased in plastic shells made through this process. The accuracy and consistency of injection molding ensure that these components fit perfectly and function reliably.

Cable Insulation

The insulation for electrical cables is often produced using injection molding. This application is essential for ensuring the safety and durability of electrical systems, preventing short circuits and other electrical issues.

Construction Industry

Fixtures and Fittings

Injection molding is used in the construction industry to produce fixtures and fittings. Items like pipe connectors, brackets, and fasteners are often manufactured using this method. The strength and durability of injection-molded parts make them suitable for various construction applications.

Decorative Elements

Decorative elements, such as moldings and trim, are also produced through injection molding. This process allows for the creation of intricate designs and patterns, enhancing the aesthetic appeal of buildings and interiors.

Aerospace Industry

Aircraft Components

The aerospace industry utilizes injection molding to produce various aircraft components. Items like interior panels, seats, and overhead compartments are often manufactured using this method. The precision and consistency of injection molding ensure that these components meet the stringent standards required in the aerospace sector.

Lightweight Parts

Injection molding helps in producing lightweight parts for aircraft. By using advanced materials like composites and high-performance plastics, manufacturers can reduce the weight of the aircraft, leading to improved fuel efficiency and performance.

Toys and Games

Toy Parts

Injection molding is widely used in the production of toys and games. Items like action figures, building blocks, and board game pieces are often manufactured using this method. The versatility of injection molding allows for the creation of various shapes, sizes, and colors, catering to the diverse preferences of children.

Game Accessories

Game accessories, such as controllers and headsets, are also produced through injection molding. This process ensures that these items are durable and have a smooth finish, providing a better user experience.

Agriculture Industry

Equipment Components

Injection molding is used in the agriculture industry to produce components for farming equipment. Items like nozzles, fittings, and protective covers are often manufactured using this method. The durability and precision of injection-molded parts ensure reliable performance in harsh agricultural environments.

Packaging Solutions

Packaging solutions for agricultural products, such as seed trays and fertilizer containers, are also produced through injection molding. The ability to create durable and lightweight packaging is essential for the efficient storage and transportation of agricultural goods.

Sports and Leisure

Sports Equipment

Injection molding is utilized in the production of sports equipment. Items like helmets, protective gear, and training aids are often manufactured using this method. The strength and durability of injection-molded parts ensure that they can withstand the rigors of sports activities.

Leisure Products

Leisure products, such as camping gear and outdoor furniture, are also produced through injection molding. This process allows for the creation of lightweight and durable items, enhancing the overall outdoor experience.

Benefits of Injection Molding Service

Cost-Effective Production

One of the primary benefits of injection molding service is cost-effective production. This method allows for the mass production of parts, reducing the overall manufacturing costs. Additionally, the efficiency of injection molding minimizes material waste, further lowering production expenses.

High Precision and Consistency

Injection molding ensures high precision and consistency in the production of parts. The ability to create complex shapes and intricate designs with tight tolerances is a significant advantage. This precision ensures that the parts fit perfectly and function reliably.

Versatility in Material Selection

Injection molding offers versatility in material selection. Various plastics, including ABS, polycarbonate, and polypropylene, can be used in this process. The ability to choose from a wide range of materials allows manufacturers to select the best option for their specific application.

Rapid Production and Turnaround

The injection molding process is known for its rapid production and turnaround times. The efficiency of this method allows for the quick creation of large quantities of parts. This rapid production capability is essential for meeting tight deadlines and market demands.

Customization and Design Flexibility

Injection molding offers customization and design flexibility. Manufacturers can create custom molds and designs based on the specific requirements of the client. This flexibility allows for the production of unique and innovative products.

Durable and Long-Lasting Parts

Injection molding produces durable and long-lasting parts. The materials used in this process are known for their strength and resilience, ensuring that the parts can withstand various environmental conditions and stresses.

Environmentally Friendly

Injection molding is an environmentally friendly manufacturing process. The efficiency of this method reduces material waste, and many of the plastics used are recyclable. Additionally, the ability to produce lightweight parts contributes to overall energy savings.

Comprehensive Support Services

Many injection molding service providers offer comprehensive support services. These services include design consultation, prototyping, mold making, and post-production support. By providing end-to-end solutions, manufacturers ensure a seamless production process from concept to final product.

Strategic Location and Logistics

Injection molding service providers are often strategically located with advanced logistics infrastructure. This ensures efficient shipping and delivery of products, reducing lead times and ensuring timely delivery to markets worldwide.

Enhanced Product Quality

Injection molding enhances product quality. The precision and consistency of this method ensure that the parts meet industry standards and specifications. This quality assurance is crucial for the reliability and performance of the final product.

FAQ

What is injection molding service?

Injection molding service is a manufacturing process that produces plastic parts by injecting molten plastic into a mold. The plastic cools and solidifies to form the desired shape.

Why is injection molding popular in various industries?

Injection molding is popular because it is cost-effective, offers high precision, allows for rapid production, and provides design flexibility. These benefits make it suitable for various applications.

What materials can be used in injection molding?

Materials used in injection molding include ABS, polycarbonate, polypropylene, polyethylene, and nylon. The choice of material depends on the specific application and desired properties.

How does injection molding benefit the automotive industry?

Injection molding benefits the automotive industry by producing lightweight, durable, and high-quality parts. It allows for the creation of complex shapes and designs, enhancing vehicle performance and aesthetics.

Can injection molding be used for medical devices?

Yes, injection molding is widely used in the medical industry to produce devices like syringes, catheters, and IV components. The precision and reliability of injection molding ensure that these devices meet stringent medical standards.

What are the advantages of injection molding in the packaging industry?

Injection molding offers advantages in the packaging industry by producing airtight, leak-proof, and durable containers. This ensures the preservation of food products and enhances the consumer experience.

How does injection molding support the electronics industry?

Injection molding supports the electronics industry by producing durable and precise component housings, connectors, and cable insulation. This ensures the reliability and safety of electronic devices.

What role does injection molding play in the construction industry?

Injection molding produces fixtures, fittings, and decorative elements in the construction industry. These parts are strong, durable, and aesthetically pleasing, contributing to the overall quality of construction projects.

Why is injection molding important for the aerospace industry?

Injection molding is important for the aerospace industry because it produces lightweight and durable components that meet stringent quality standards. This enhances aircraft performance and safety.

How does injection molding benefit the toy industry?

Injection molding benefits the toy industry by producing diverse, durable, and safe toy parts and accessories. The process allows for the creation of various shapes, sizes, and colors, catering to children’s preferences.

What are the environmental benefits of injection molding?

Injection molding is environmentally friendly because it reduces material waste, uses recyclable plastics, and produces lightweight parts that contribute to energy savings.

Conclusion

Injection molding is a versatile and efficient manufacturing process with numerous applications across various industries. From automotive and medical to consumer goods and electronics, injection molding plays a crucial role in producing high-quality, durable, and cost-effective parts. The benefits of this method, including precision, customization, and rapid production, make it an ideal choice for companies worldwide.

By understanding the top applications of injection molding, businesses can leverage this technology to enhance their products and gain a competitive edge in the market. Whether you are in the automotive, medical, or packaging industry, injection molding offers reliable and innovative solutions to meet your manufacturing needs.

Import from China Guide

For beginners who don’t know what to buy & sell, have 0 experience about importing from China, you can get all questions answered in this tutorial.

(10 video courses included)