Top 10 Benefits of Injection Molding Service in China

Injection molding is a crucial manufacturing process used to produce plastic parts for various industries. In recent years, China has emerged as a leading provider of injection molding services, offering numerous benefits to companies worldwide. In this blog post, we will explore the top 10 benefits of utilizing injection molding service in China. This article will provide you with valuable insights into why China is a preferred destination for injection molding services.

1. Cost-Effective Injection Molding Service

One of the primary benefits of choosing injection molding service in China is cost-effectiveness. Chinese manufacturers offer competitive pricing due to lower labor and production costs. This allows companies to reduce manufacturing expenses without compromising on quality. Consequently, businesses can allocate their budget to other critical areas such as research and development or marketing.

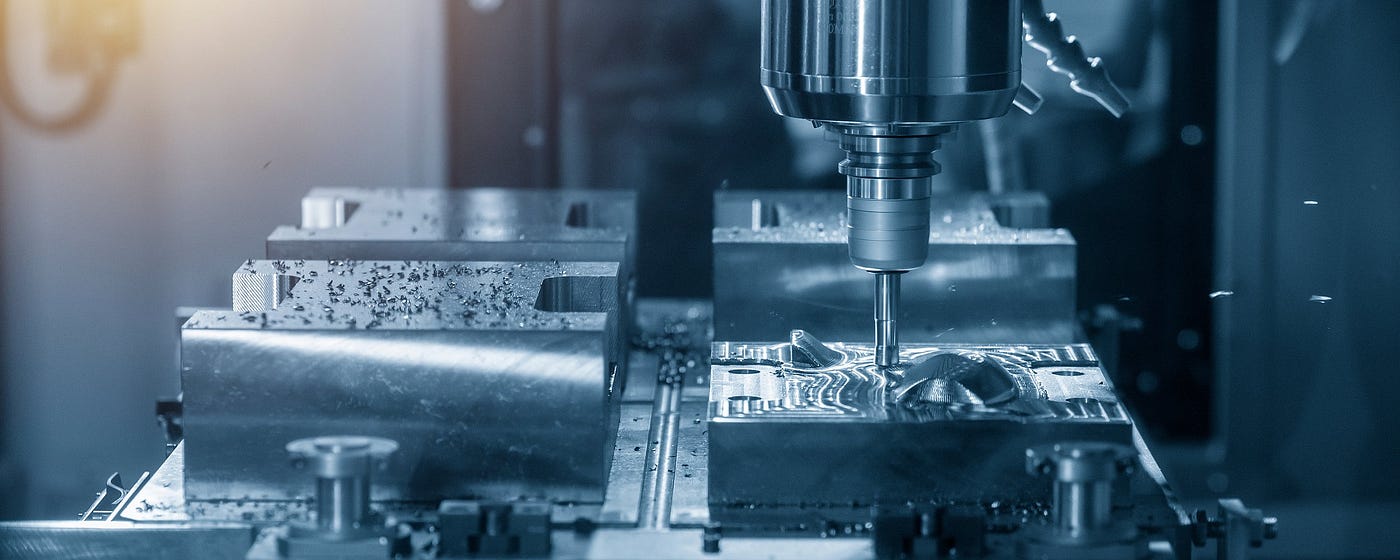

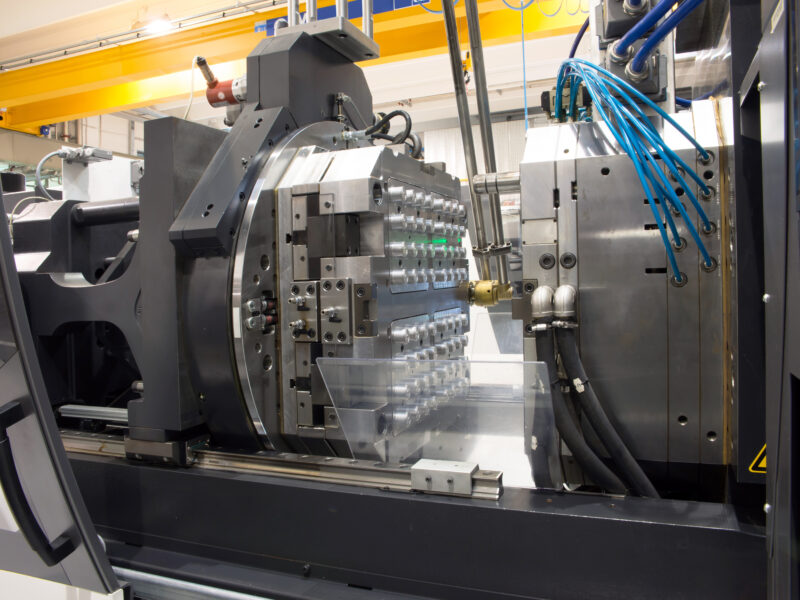

2. High-Quality Production Standards

Chinese injection molding service providers adhere to stringent quality control measures. They use advanced machinery and technologies to ensure high-quality production. Moreover, many manufacturers are ISO certified, indicating their commitment to maintaining global quality standards. This guarantees that the plastic parts produced are durable and meet industry specifications.

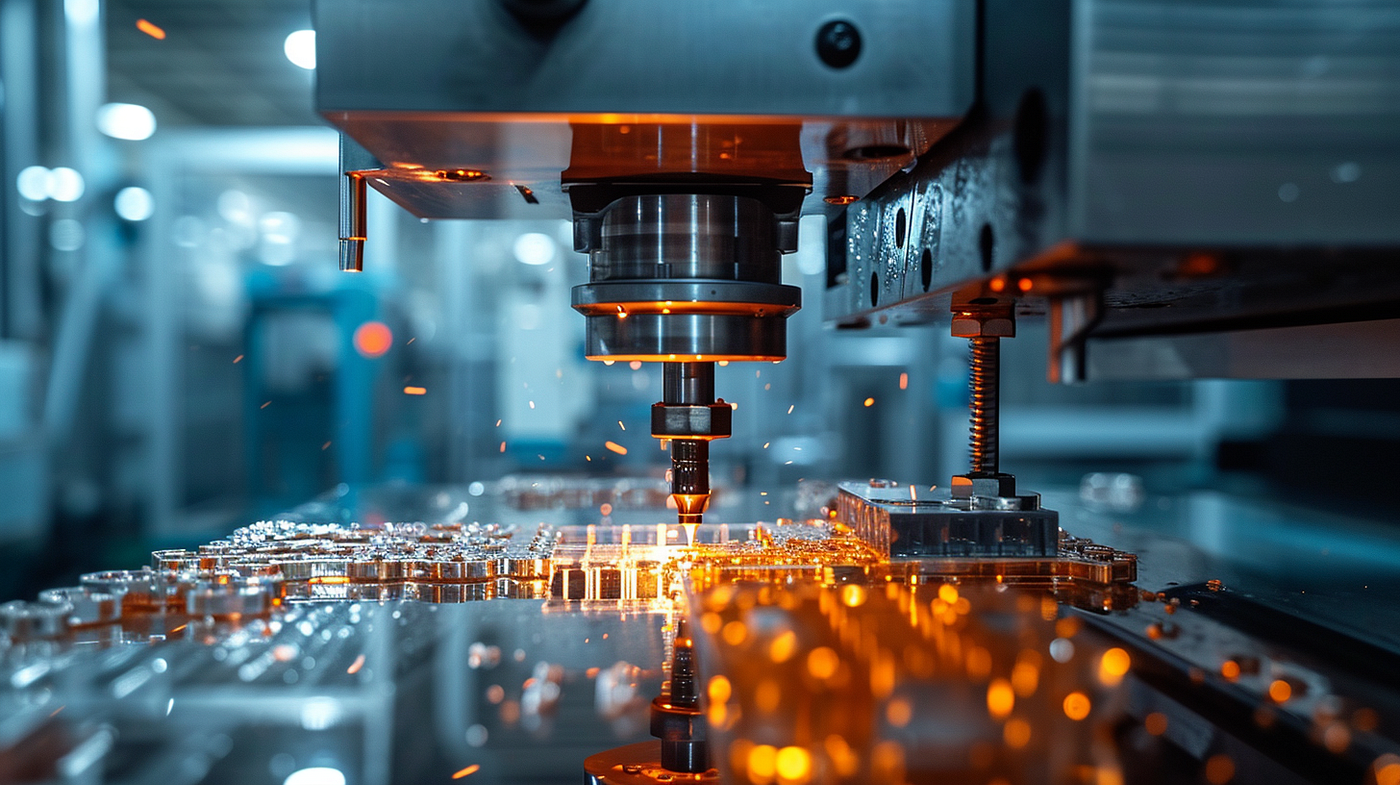

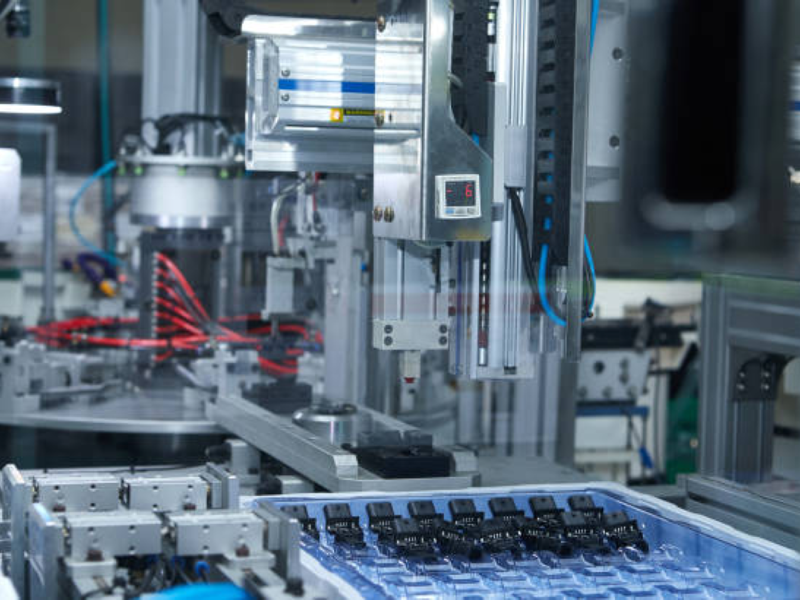

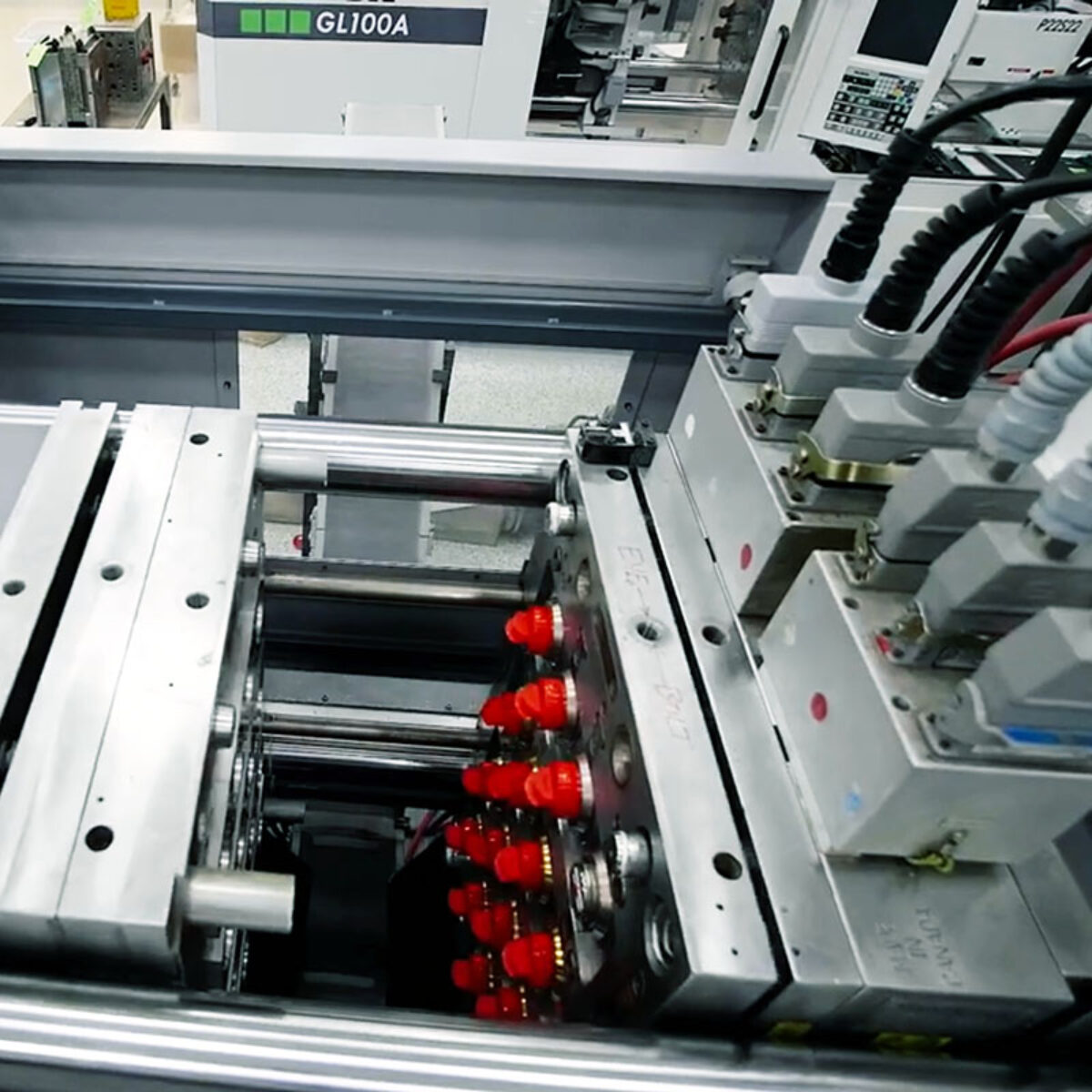

3. Access to Advanced Technologies

China’s injection molding service industry is equipped with state-of-the-art technologies. These include automated machinery, robotics, and precision molding techniques. Utilizing these advanced technologies, Chinese manufacturers can produce complex and intricate designs with high accuracy. As a result, companies can benefit from innovative and precise injection molding solutions.

4. Fast Turnaround Times

Chinese injection molding service providers offer fast turnaround times, enabling businesses to meet tight deadlines. The efficiency of Chinese manufacturers is attributed to their streamlined production processes and large-scale operations. This allows companies to get their products to market faster, gaining a competitive edge.

5. Extensive Experience and Expertise

China has a long history of manufacturing, and its injection molding service industry is no exception. Chinese manufacturers have extensive experience and expertise in the field, which ensures reliable and high-quality production. Their knowledge of various industries allows them to cater to specific requirements and deliver tailored solutions.

6. Scalability of Production

Injection molding service in China offers scalability, making it suitable for both small and large-scale production runs. Chinese manufacturers can easily adjust their production capacity to meet the needs of different projects. This flexibility allows companies to scale their operations without significant disruptions or delays.

7. Wide Range of Materials

Chinese injection molding service providers offer a wide range of materials to choose from. These include various types of plastics such as ABS, polycarbonate, and polypropylene. Having access to diverse materials allows companies to select the best option for their specific application, ensuring optimal performance and durability.

8. Customization and Design Flexibility

Customization is a significant advantage of utilizing injection molding service in China. Chinese manufacturers can produce custom molds and designs based on the specific requirements of the client. This design flexibility allows companies to create unique and innovative products that stand out in the market.

9. Comprehensive Support Services

Many Chinese injection molding service providers offer comprehensive support services. These include design consultation, prototyping, mold making, and post-production services. By providing end-to-end solutions, Chinese manufacturers ensure a seamless production process from concept to final product.

10. Strategic Location and Logistics

China’s strategic location and advanced logistics infrastructure make it an ideal choice for injection molding services. The country’s well-developed transportation networks facilitate efficient shipping and delivery of products. This reduces lead times and ensures timely delivery to international markets.

Frequently Asked Questions (FAQ)

What is injection molding service?

Injection molding service is a manufacturing process used to produce plastic parts by injecting molten plastic into a mold. It is widely used in various industries, including automotive, electronics, and consumer goods.

Why should I choose injection molding service in China?

Choosing injection molding service in China offers numerous benefits, including cost-effectiveness, high-quality production, access to advanced technologies, fast turnaround times, and extensive experience.

How do I ensure the quality of injection molding services in China?

To ensure quality, select manufacturers with ISO certifications and positive reviews. Additionally, request samples and conduct quality inspections before placing large orders.

What materials are commonly used in injection molding?

Common materials used in injection molding include ABS, polycarbonate, polypropylene, polyethylene, and nylon. The choice of material depends on the specific application and desired properties.

Can I get custom injection molding services in China?

Yes, many Chinese injection molding service providers offer customization options. They can produce custom molds and designs based on your specific requirements.

How long does the injection molding process take?

The duration of the injection molding process varies depending on the complexity of the design and the production volume. Chinese manufacturers are known for their fast turnaround times, ensuring timely delivery.

What industries use injection molding services?

Injection molding services are used in various industries, including automotive, electronics, medical, consumer goods, and packaging.

Are Chinese injection molding services reliable?

Yes, Chinese injection molding services are reliable. Many manufacturers adhere to global quality standards and have extensive experience in the industry.

How do I find a reputable injection molding service provider in China?

To find a reputable provider, research online reviews, ask for recommendations, and evaluate the manufacturer’s certifications and capabilities.

What are the benefits of using advanced technologies in injection molding?

Advanced technologies in injection molding improve precision, efficiency, and design flexibility. They enable the production of complex and high-quality plastic parts.

Conclusion

In conclusion, injection molding service in China offers numerous benefits that make it an attractive option for businesses worldwide. From cost-effectiveness and high-quality production to access to advanced technologies and fast turnaround times, Chinese manufacturers provide reliable and efficient solutions. Additionally, their extensive experience, scalability, and customization options further enhance the appeal of injection molding services in China.

For companies seeking high-quality plastic parts and components, partnering with a reputable Chinese injection molding service provider can lead to significant advantages. The strategic location and logistics infrastructure of China also ensure timely delivery to international markets. By choosing injection molding service in China, businesses can achieve their production goals while maintaining competitive pricing and superior quality.

Whether you are a small startup or a large corporation, the benefits of injection molding service in China can help you streamline your manufacturing processes and achieve success in your industry.

Import from China Guide

For beginners who don’t know what to buy & sell, have 0 experience about importing from China, you can get all questions answered in this tutorial.

(10 video courses included)