Three Common Injection Molding Defects and Strategies for Prevention

Injection molding, a highly efficient production technique for generating large quantities of identical parts, demands a significant level of technical proficiency to master. The intricate interplay of numerous variables means that even minor oversights in the initial stages of product development can escalate into significant issues, potentially compromising the integrity of the final product.

Defects can disrupt the pace and cost-effectiveness of the entire product development cycle, and if left unaddressed, they may curtail the lifespan of the product. Injection molding problems and defects can stem from various sources such as flawed design, errors in the production process, lapses in quality control, and more. Hence, it is crucial to adopt a proactive stance towards risk mitigation across all phases of product development to minimize the likelihood of encountering injection molding defects.

Outlined below are some prevalent defects that can manifest in plastic injection molding processes, along with strategies that product teams can employ to circumvent them:

- Flow Lines

Flow lines manifest as discolored streaks or patterns on the surface of a part. These anomalies result from the uneven movement of molten plastic within the injection mold, causing the resin to solidify at varying rates. Typically, this indicates that injection speed and/or pressure are inadequate. Flow lines can also arise when the thermoplastic resin traverses regions of the mold with varying wall thicknesses. Thus, maintaining uniform wall thickness or ensuring appropriate lengths of chamfers and fillets is crucial to mitigate this issue. Placing the gate in a thin-walled segment of the tool cavity can additionally aid in minimizing flow lines.

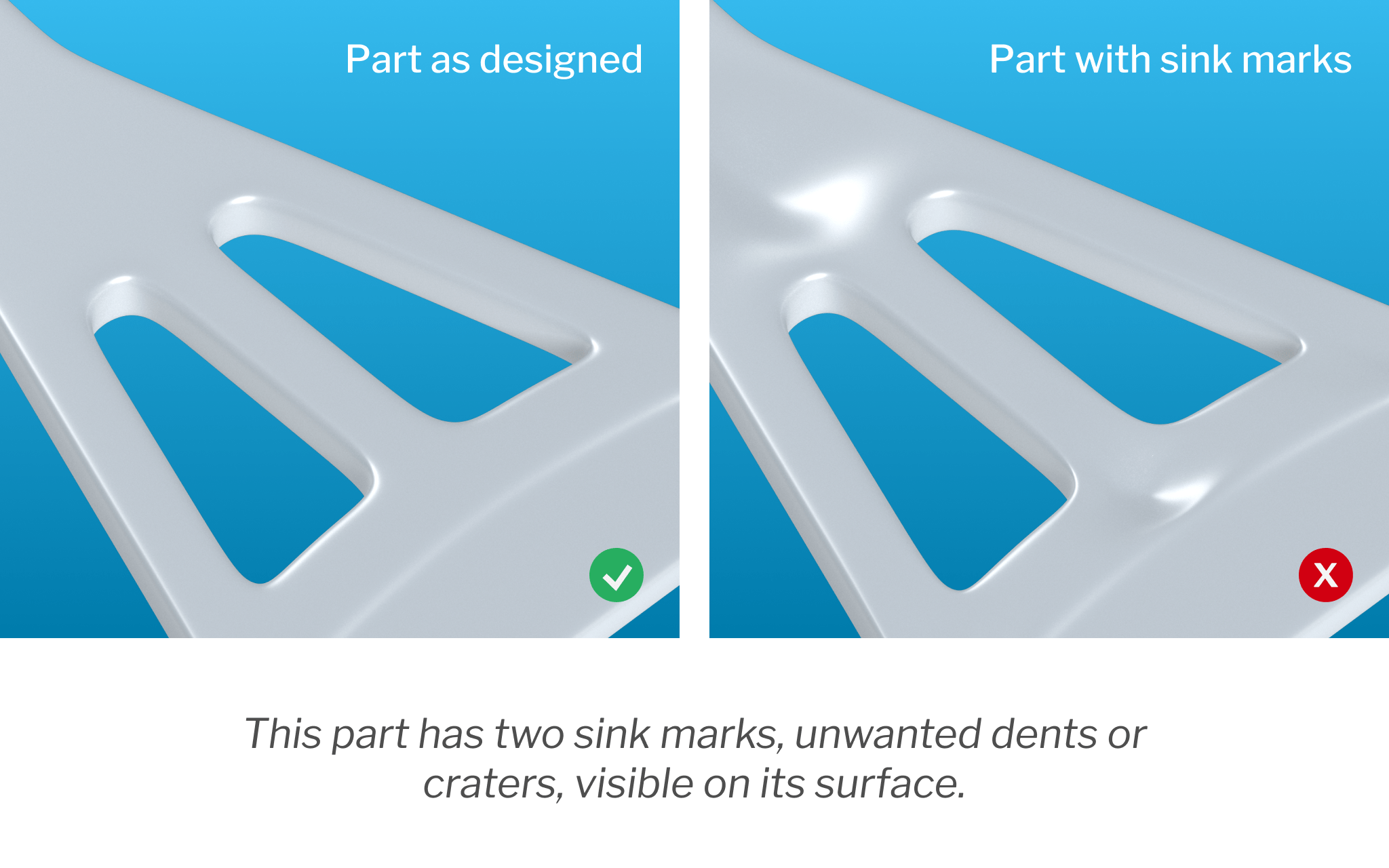

Flow lines can also arise when the thermoplastic resin traverses regions of the mold with varying wall thicknesses. Thus, maintaining uniform wall thickness or ensuring appropriate lengths of chamfers and fillets is crucial to mitigate this issue. Placing the gate in a thin-walled segment of the tool cavity can additionally aid in minimizing flow lines. - Sink MarksSink marks manifest as depressions, dents, or craters in thick segments of a part. The prolonged cooling time of thicker sections can lead to an unexpected consequence: inner portions of the part shrinking and contracting at a different rate compared to the outer regions.Though typically indicating that the plastic requires more time within the mold for adequate cooling and curing, sink marks can sometimes be alleviated by reducing the thickness of the thickest wall sections. This adjustment promotes more uniform and thorough cooling. Insufficient pressure in the mold cavity or excessively high temperatures at the gate can also contribute to the formation of sink marks.

Injection Molding Defects

From a design perspective, minimizing the risk of sink marks involves ensuring appropriate injection molding rib thickness and wall thickness. These measures not only mitigate sink marks but also enhance the overall structural integrity of the part.

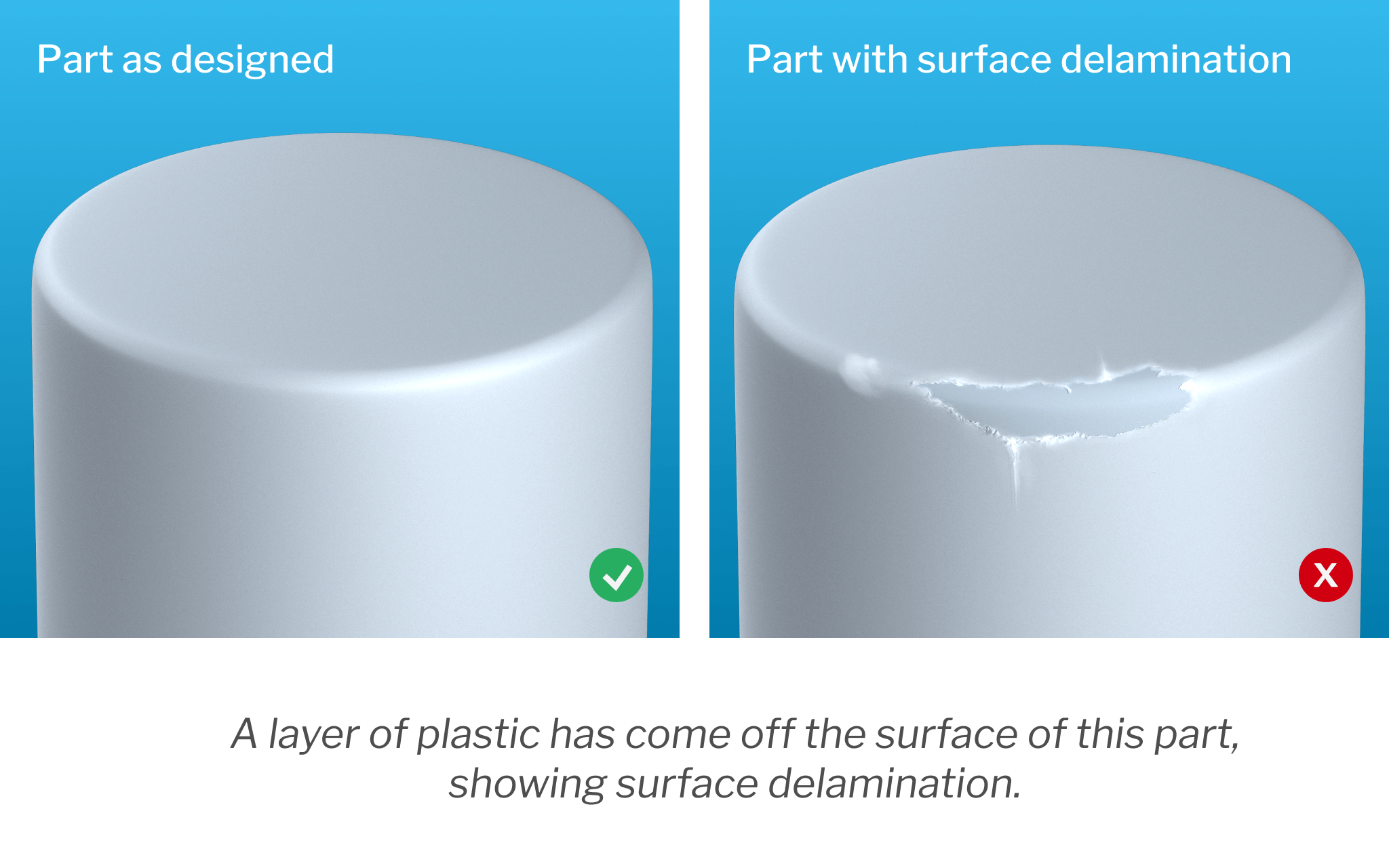

- Surface DelaminationDelamination refers to a condition where a part’s surface separates into thin layers, resembling peelable coatings. This separation results from the presence of contaminants in the material that fail to bond with the plastic, leading to localized flaws. Over-reliance on mold release agents can also trigger delamination.To address and prevent delamination, teams should elevate mold temperatures and optimize the mold ejection mechanism to reduce reliance on mold-release agents, which can heighten the risk of delamination. Properly pre-drying the plastic before molding can also aid in mitigating this issue.

Optimizing Your Injection Molding Process

Import from China Guide

For beginners who don’t know what to buy & sell, have 0 experience about importing from China, you can get all questions answered in this tutorial.

(10 video courses included)